The Evolution of Machine Tools: From Manual Operations to Smart Manufacturing

Machine tools have played a pivotal role in the advancement of human civilization, facilitating the transition from manual labor to automated precision. Over centuries, machine tools have evolved from rudimentary hand-operated devices to sophisticated, computer-controlled systems that drive modern manufacturing. This article explores the historical progression of machine tools, their impact on industry, and the emergence of smart manufacturing in the 21st century.

The Dawn of Machine Tools: Manual Beginnings

The origins of machine tools date back to ancient times when artisans relied on simple hand tools for shaping materials. Early civilizations, such as the Egyptians and Greeks, utilized rudimentary chisels, hammers, and lathes to carve wood, stone, and metal. However, the real transformation began in the late Middle Ages with the introduction of mechanical devices powered by human effort or water wheels.

One of the earliest known machine tools was the bow lathe, which was manually operated and used to shape cylindrical objects. The development of the treadle lathe in the 15th century marked a significant step forward, allowing craftsmen to use foot power to drive rotating workpieces. These primitive machines laid the groundwork for more advanced machine tools in the centuries to come.

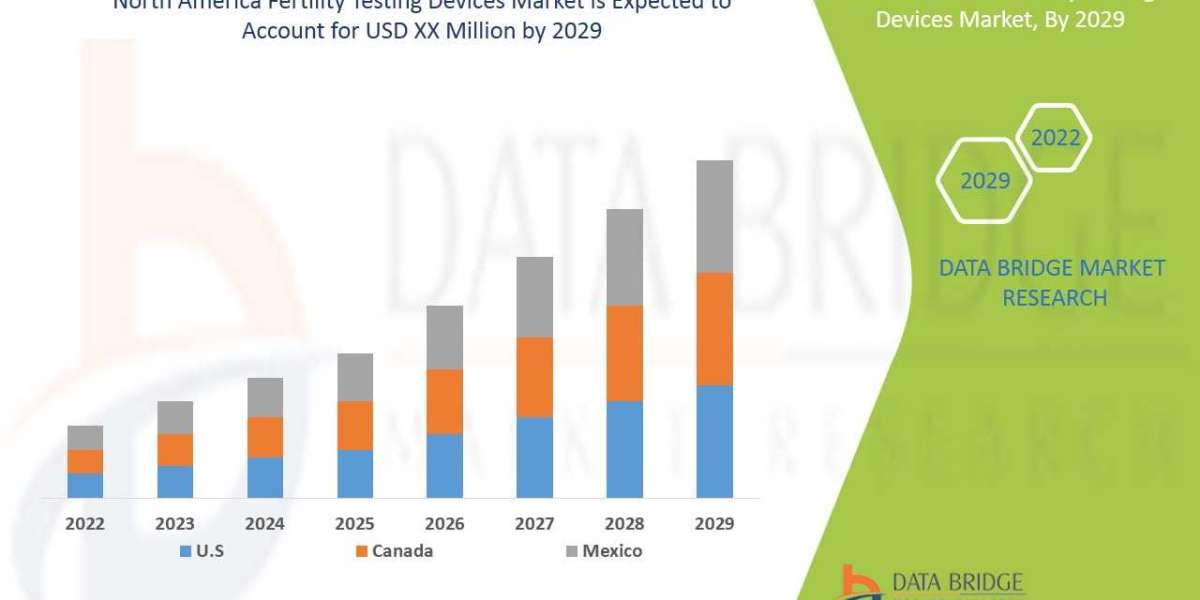

According to a Machine Tools Market report, the industry is expected to grow significantly in the coming years.

The Industrial Revolution: Mechanization and Precision Engineering

The Industrial Revolution (18th and 19th centuries) was a turning point in the evolution of machine tools. The advent of steam power and mechanized production methods revolutionized manufacturing processes, leading to unprecedented levels of efficiency and precision. Pioneers such as James Watt, Henry Maudslay, and Joseph Whitworth made significant contributions to machine tool development.

Henry Maudslay, often regarded as the "father of the machine tool industry," invented the screw-cutting lathe in the late 18th century. This innovation enabled mass production of standardized screws and bolts, laying the foundation for interchangeable parts in manufacturing. Maudslay’s lathe incorporated a leadscrew and slide rest, which allowed for precise machining of metal components.

Joseph Whitworth further refined precision engineering by developing measurement standards and high-accuracy surface plates. His innovations played a crucial role in improving the consistency and quality of manufactured goods. During this era, machine tools such as milling machines, planers, and shapers emerged, enhancing the ability to fabricate complex metal parts with greater accuracy.

The 20th Century: Automation and Numerical Control

The 20th century witnessed a technological leap with the introduction of electrical power and automation in manufacturing. The development of electric motors allowed machine tools to operate with greater efficiency and reduced reliance on manual labor. However, the most groundbreaking advancement came in the 1950s with the invention of Numerical Control (NC) machines.

John T. Parsons, an American engineer, is credited with pioneering numerical control technology, which used punched cards to guide machining operations. This innovation led to the development of Computer Numerical Control (CNC) systems in the 1960s, where computers replaced manual programming to control machine tools with unparalleled precision.

CNC machines revolutionized the manufacturing industry by enabling mass production of complex components with minimal human intervention. Machines such as CNC lathes, milling centers, and grinders became commonplace in industries ranging from aerospace to automotive. The ability to automate machining processes significantly reduced production time, increased accuracy, and enhanced overall efficiency.

The Digital Age: Integration of CAD/CAM and Robotics

As computing technology advanced, so did the capabilities of machine tools. The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software allowed engineers to design intricate components digitally and translate them into machining instructions with ease. This seamless connection between design and manufacturing improved productivity and reduced errors.

The late 20th and early 21st centuries saw the rise of robotics in machining processes. Robotic arms equipped with precision tools enhanced automation by performing repetitive tasks such as drilling, welding, and assembly. These robotic systems not only increased efficiency but also improved workplace safety by reducing human exposure to hazardous environments.

Additionally, advancements in sensors, artificial intelligence (AI), and the Internet of Things (IoT) paved the way for smart manufacturing. Modern CNC machines are now equipped with real-time monitoring systems that detect tool wear, optimize cutting parameters, and predict maintenance needs. This predictive maintenance approach minimizes downtime and maximizes operational efficiency.

The Era of Smart Manufacturing: Industry 4.0 and Beyond

Today, the manufacturing industry is undergoing a paradigm shift with the advent of Industry 4.0, a term used to describe the fusion of digital technologies with industrial processes. Smart manufacturing leverages data analytics, cloud computing, and interconnected machinery to create highly adaptive and efficient production environments.

One of the key elements of Industry 4.0 is the concept of the "smart factory," where machine tools communicate with each other and make autonomous decisions based on real-time data. Sensors embedded in CNC machines collect vast amounts of information, which is then analyzed to optimize performance. This level of connectivity enhances production flexibility and enables manufacturers to quickly respond to changing market demands.

Another significant trend is the use of Additive Manufacturing (AM), commonly known as 3D printing. While traditional machine tools rely on subtractive processes (removing material to shape a component), 3D printing builds objects layer by layer. This technology is transforming industries by allowing rapid prototyping, customization, and reduced material waste.

Artificial intelligence is also playing a crucial role in the evolution of machine tools. AI-powered algorithms analyze machining data to improve toolpath strategies, reduce errors, and enhance surface finishes. Machine learning models can predict tool failures and suggest corrective actions, further boosting efficiency and reducing production costs.

The Future of Machine Tools: Towards Full Automation and Sustainability

Looking ahead, the future of machine tools is poised for even greater advancements. The integration of quantum computing and blockchain technology could enhance data security and optimize complex machining processes. Fully autonomous manufacturing systems, driven by AI and robotics, may eliminate the need for human intervention entirely.

Sustainability is also becoming a major focus in machine tool development. Energy-efficient machining, eco-friendly coolant systems, and the use of recycled materials are being explored to minimize the environmental impact of manufacturing. Companies are investing in closed-loop systems that reduce waste and enhance resource efficiency.

As industries continue to evolve, machine tools will remain at the forefront of technological innovation. The journey from manual operations to smart manufacturing is a testament to human ingenuity and the relentless pursuit of efficiency. With ongoing advancements in AI, automation, and sustainable practices, the future of machine tools promises to be both intelligent and environmentally responsible.

Conclusion

The evolution of machine tools has been a remarkable journey, transforming industries and shaping the modern world. From simple hand-operated devices to AI-driven smart factories, machine tools have continuously evolved to meet the demands of precision, efficiency, and automation. As we move towards a future dominated by smart manufacturing, the possibilities for innovation are boundless. Embracing these advancements will not only enhance productivity but also pave the way for a more sustainable and interconnected industrial landscape.